| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Linquan |

| Model Number : | KYLIN 770 |

| Certification : | CE , ISO9001 , Patent |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 5 Machine/month |

| Delivery Time : | 1-3 month |

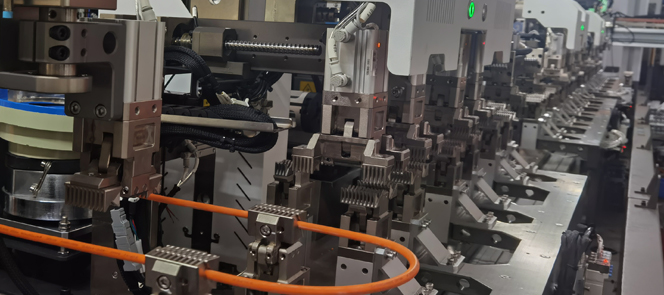

Automatic Terminal High Voltage Cable Machine Double Crimping Both-end Insertion

Equipment Overview

1. It is mainly used for automatic high-voltage cable processing,

which can complete the functions of wire feeding, peeling, weaving

net,

copper close-loop crimping, inner core peeling, waterproof plug,

terminal crimping, sheath and so on.

2, The whole machine adopts PLC bus control communication and a

full servo power system, which guarantees stable performance.

3,Touch screen operation. All processing parameters can be saved

and production content can be edited and sent upon request.

4, With imported servo motor and CCD visual detection function, it

gives you a real-time monitoring of the process quality to ensure

product

yield.

5, The machine adopts high precision servo motor and PM-01 pressure

management system, high precision and strong stability, real-time

monitoring of the process.

Technical Parameters

| Function | Fixed length cutting at both terminals, stripping, double-terminal crimping, double-terminal inserting,Waterproof plug inserting, adjust height on touch screen, drawing force inspection, discharge defective products while selecting | Capacity | 18 sec per single-sided loading (Piece output depends on wire length and housing/terminal combinations) |

| Crimping Capacity | 10 tons and15 Tons Servo motor with mute specification (Customized according to the requirements of products) | Block Feed | Linear-carrier housing transferring/ Plate-loop conveying housing

feeding module (According to customer requirements) |

| Wire Cross-sections | 2.5 – 16 mm² (AWG 14 – 5) | Process Monitoring (integrated) | CCD Terminal Detection Crimping Force Monitoring Insertion Force Monitoring |

| Feeding Wire Length | 600-9999mm | Electrical Connection | 3 phase/380v/50HZ(machine comes with a transformer) |

| Outer Skin Cutting | 0-60mm, stripping precision ±0.5mm can be full stripping and half stripping; The cutting precision is 0.05mm | Power | 25KW |

| Laser stripping aluminum foil | 3-50mm, the residual size of one circle of aluminum foil is less than the thickness of the outer insulation skin, the residual size of sharp corner is less than or equal to 4.5mm, and the cutting accuracy is ±1mm, which does not hurt the woven net and insulation skin | Compressed Air | 0.5-0.7Mpa |

| Screening Can Cutting | 5-55mm, cutting accuracy ±0.4mm | Optional | Max.12 PCS Crimping Module ((with programmable crimp height) |

| Screening Can Reversal | 5-20mm | Quality Assurance | Pull force Height Crimp-height Measurement Seal Module RXM Linquan MES System Laser Inkjet Print Tinning Twisting Stranded Wire |

| Inner Skin Cutting | 0-55mm, stripping precision ±0.5mm can be full stripping and half stripping; The cutting precision ±0.05mm |

Our advantages:

Outstanding-speed mass manufacturing capability

Fantastic compatibility

Reliable machine performance

Consumer-friendly HMI

Well-matched with third-party data (which includes MES and SCADA)

interface

Flexible platform design

Quick changeover time

Real-time equipment performance and process data

Easy-to-manipulate part number list

Modular layout, including standard housing insertion, crimping, CCD

modules

Standardized and modular layout

Exceptional quality control ensured through CCD on all processes

Short changeover time

MES Traceability

Details:

The KYLIN Series is specially designed for high voltage Harness

manufacturing. Can produce kinds of high

voltage harnesses of varying degrees of complexity.

It has the functions of Both-end measuring, cutting, Both-end

striping, Both-end crimping, Inner and outer

skin cutting, Screening can cutting, Screening can reversal,

Both-end Insertion and so on. Reduce production

time significantly.

These machines make it possible to manufacture a range of high

voltage harnesses. Greatly saving labour cost.

Precision transmission and alignment

Professional high-voltage line transmission module, to achieve

precise transmission of different specifications of high-voltage

wire.

During transmission, the wire is straightened synchronously to make

its transmission smoother and more accurate.

Automated inkjet printers mark the wires

The marked wires are picked up by a shuttle system and guided in

loops to the processing machines.

Continuous data flow and traceability Production data can be sent

directly to the machine via a network. The quality data from the

production process is saved for each wire harness and traceability

is guaranteed at all times.

Cutting Precision

It is based on a capacitive measuring principle, is integrated in

the blade holder and can be operated using any standard stripping

blade.

The sensitivity of the monitoring can be configured using setting

parameters.

Defective wire ends are detected automatically and rejected.

Cutting length shorter than 600mm, error range 0.5mm+

Self-Developed Crimping Head

Pass CPA+ pressure stability test CMK can reach to 4.0 or

higher,far higher than the industry standard 1.6(Detailed data

reports

can be provided)

Higher stability and accuracy

Adjust height on touchscreen

The crimping machine head,Laser stripping aluminum foil, Screening

Can cutting and can be added according to customers need.

The equipment is modular and can be matched according to product

types.

Self-Developed CCD Visual Inspection

CCD Visual Inspection detect the Coreless crimping, Crimping

without stripping, Deep and shallow crimping, Core wire splay, Half

packing of insulation layer and provide alarm.

Core Wire Online Inspection System

Detect the Copper Wire Inspection Number and Stripping Length

Inspection and provide alarm.

Self-Developed Online Pressure Inspection

Detect the Terminal Presence, Deep or shallow crimping and Coreless

crimping and provide alarm.

Magnetic Levitation Linear Motor

Fast handling Speed

Top position accuracy

Quiet, long service life, low maintenance cost

High precision

Untwisting of the wires

Unwound wires are always twisted. A specially designed untwisting

module untied the wire. The wires are then 100% straight, which is

crucial for the subsequent fully automatic insertion.

Special adjustment device for final harness

Automatic wiring harness adjustment device, free hands, one step to

complete the finished product

Processing samples

|