| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | LINQUAN |

| Model Number : | LOONG-860E |

| Certification : | ISO9001, CE |

| Price : | USD $ 66,000~500,000 per set |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 5 machine per month |

| Delivery Time : | 1-3 Months |

Wire Harness Machine Double End Terminal Crimping And Inserting

Equipment

The Loong Series Harness Manufacturing can produce more wire

harnesses of varying degrees of complexity.

It has the functions of Both-end measuring cutting, Both-end

striping, Both-end crimping, Both-end Insertion and so on.

Reduce production time significantly.

3 or 12 modules can be selected, as required.

The Loong Series is a better choice for miniaturization and

increasingly smaller batches.

These machines make it possible to manufacture a range of different

wire harnesses.

Technical Parameters:

| Wire Size | 0.13-4.0mm2 |

| Feeding Length | 450-9999mm |

| Stripping Length | Full strip: 0-15mm Half strip: 0-15mm |

| Power Source | China - 380V/ 3 Phase / 50Hz Canada - 600V/ 3 Phase / 60Hz USA/Japan - 480V/ 3 Phase / 60Hz Mexico/Honduras - 480V/ 3 Phase / 60Hz Europe - 400V/ 3 Phase / 50Hz |

| Power | 10KW |

| Wire Selector | Max.50 wires(Different color & cross-section) |

| Penetraction Depth | Max. 3mm |

| Air Pressure | 0.5Mpa |

Cutting Precision | Cutting length*0.02mm |

| Stripping Capacity | 3 TON presser |

| Wire End Storage | Rotary storage unit with a maximum of 30 storage spaces |

| Connector Types | 30 kinds of the connectors |

| Mould Assembly Type | AS40, AS42, AE30(Pneumatic mould can be customized) |

| QC Contents | Wire presence, Wire overload, Terminal presence, Terminal overload, Stripping and crimping visual monitoring, Crimping force monitoring, Insertion & pull-back force monitoring |

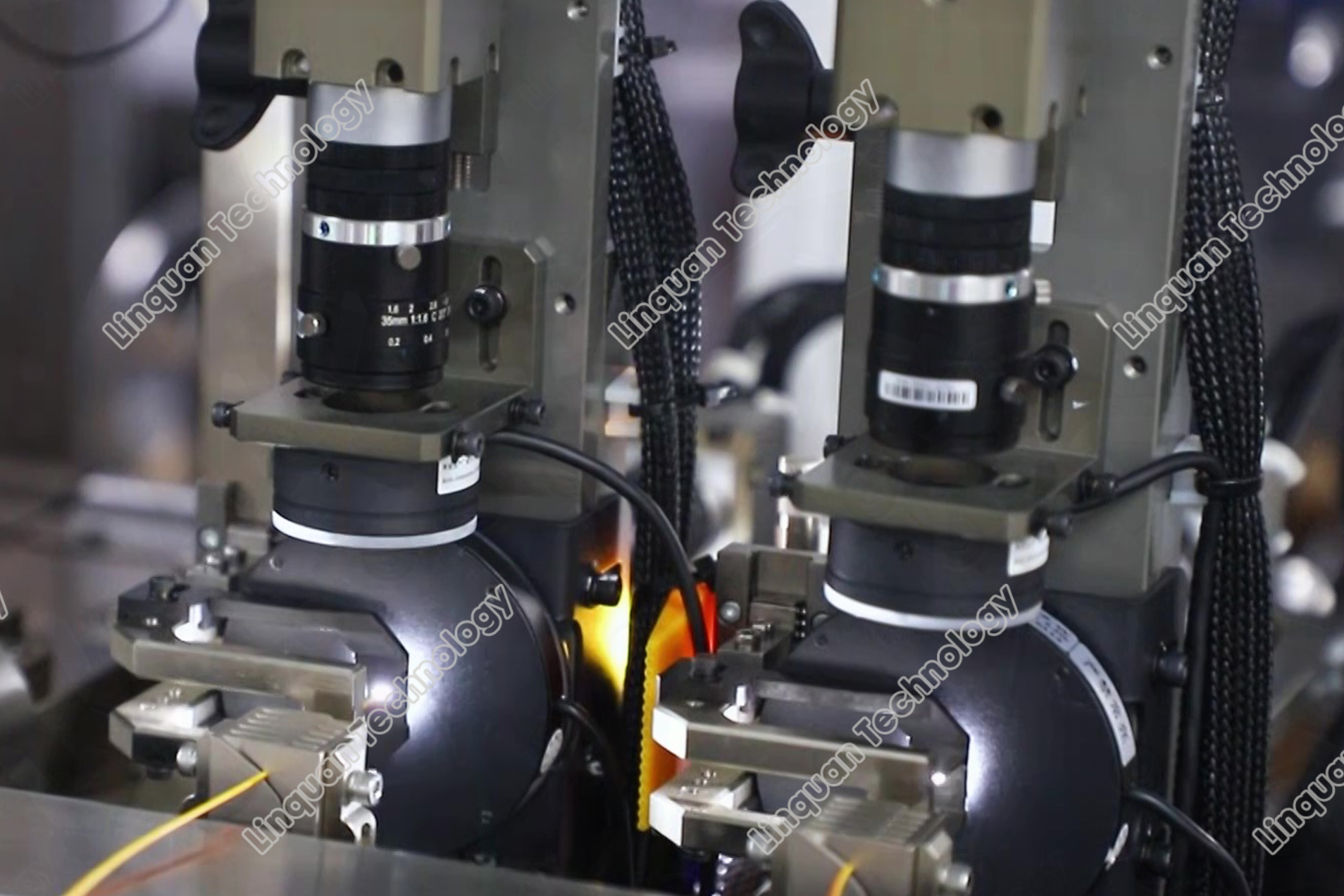

| QC Devices | CCD inspection modules, Crimping Force Monitoring (Force sensor), Insertion/Pull-back Force Monitoring (Force sensor), Terminal crimped height measuring instrument, Terminal pull force measuring instrument |

| Efficiency | Both-end crimping and insertion about 1000pcs/hr (Depends on different producing process and the functional module quantity, productivity is different) |

Functions | Pre-feeding, Wire feeding, Fixed length cutting, Stripping, Both-end crimping, Both-end insertion, Adjusting crimp height on HMI, Unloading defective products through CCD inspection |

| Optional | Lin Quan MES System, Laser Inkjet Print, Seal insertion (Max 6 modules), Tinning & Twisting, Wire Stranding, Wire end solidifying, Splicing & welding, Double crimping, Max.12 Crimping Modules (with programmable crimp height), Linear-carrier housing feeding/ Plate-loop conveying housing feeding module (According to customer requirements) |

Our advantages

Precisely cutting

Cutting length lesser than 100mm,

error range 0.5mm+

Self-Developed Crimping module

Pass CPA+ pressure stability test CMK can reach to 4.0 or higher,

far higher beyond the industry standard 1.67(Detailed data reports

can be provided)

High stability and accuracy

Adjusting height on touchscreen

100% quality inspection at production line

Magnetic Levitation Linear Motor

Fast handling Speed

High position accuracy

Quiet operation process

Long service life

Low maintenance cost

High precision inserting unit

Self-Developed crimping vision monitor

Insulation barrel errors

One strand out

Low conductor

High insulation

Seal insert errors (seal positions, cut seal, reversed insert,

etc.)

Core Wire Online Inspection System

Detect the Copper Wire Inspection Number and Stripping Length

Inspection and provide alarm.

Self-Developed CFM(Crimping Force Monitor)

Detect the terminal presence, deep or shallow crimping and coreless

crimping and provide alarm.

Crimping Module(C202)

Servo-controlled press assures best crimping result.

Integrated with independent crimping force monitoring unit.

Maximum 12 crimping stations could be applied.

Crimping parameters, e.g., crimping height, could be set, adjusted

and displayed at HMI.

Wire Selector

Compatible for maximum 50 different wires works synchronously.

Tool-free quick guide tube changeover 0.13-4mm²(AWG26-11).

Cutting and Stripping Module

Applying double high-speed blades(V-shape/R-angle blade).

Adjust stripping data with HMI to achieve ultra precision and clean

stripping.

Cutting & stripping variety of cross-section wires without

complicate change-over step.

Untwisting Module

Remove wire twists.

Decline scrap rate.

CCD Visual Inspection (TDVM-1)

Integrated QC module, efficient quality monitoring.

Stripping, crimping and center conductor inspection.

Real-time monitoring producing process.

In time detecting scraps.

Wire Storage Unit

30 storage positions.

Optimize insertion sequence: from left to right, button to top.

Breakthrough insertion limitations.

Special design for sophisticate wire harnesses.

Plate-loop Conveying Connector Loading Module

Equipped with two conveying plates, efficient connector reloading.

Versatile connectors loading synchronously.

Enable sequence product producing.

Quick & easy manual final product unloading.

Insertion Module

Dual insertion clamps structure, ensuring insertion accuracy,

stability and efficiency.

Segmented insertion process, integrated insertion and pull-back

force detection, declining scrap rate.

|